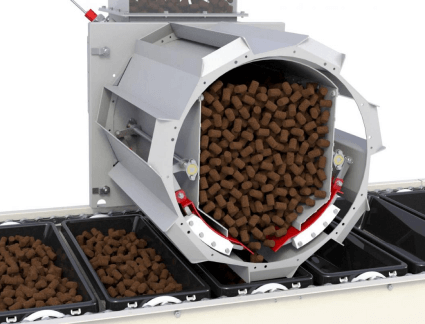

Simatek Drum Feeder

The patented Simatek Drum Feeder is the ideal feeding system for conveying fragile products – both easy and poor flowing products.

The system fills the buckets continuously and separately without waste – no overlap required. The function makes it possible to convey with low chain speed in combination with a high filling degree resulting in an increased capacity. This optimisation also ensures minimum dust generation.

The gap between the buckets eliminates the need for most guides. Only a forced guidance of the buckets at emptying is needed, which results in significant cost savings on wearing parts and a substantial enhanced operational reliability.

The integrated dosing damper valve is controlled electronically from the enclosed control unit or directly from PLC. The feeding system is executed in an ”easy-to-clean” design, which makes it possible to open and disassemble the main components in few minutes. This is a reliable and gentle feeding system specially suited for the process industry for conveying fragile as well as abrasive products.

The drum feeder may be retrofitted on existing elevators.

Advantages:

- High capacity at a low speed

- Gentle product feeding with optimum bucket filling

- Minimum forced guidance of the elevator buckets = less wear

- ”Easy to clean” design

- Increased operating reliability and limited service needs

- Minimum dust generation when conveying dusty products

- The drive of the drum requires no further electrical installation or energy supply

- Integrated electrically controlled dosing damper valve

Applications

- Easy-running

- Poor flowing

- Fragile and abrasive products

Product example

- Sugar

- Powder

- Corn

- Enzymes

- Catalysts

- Detergents

- Minerals

- Metal oxides