Intermediate Outlet

A Gentle and Flexible Solution

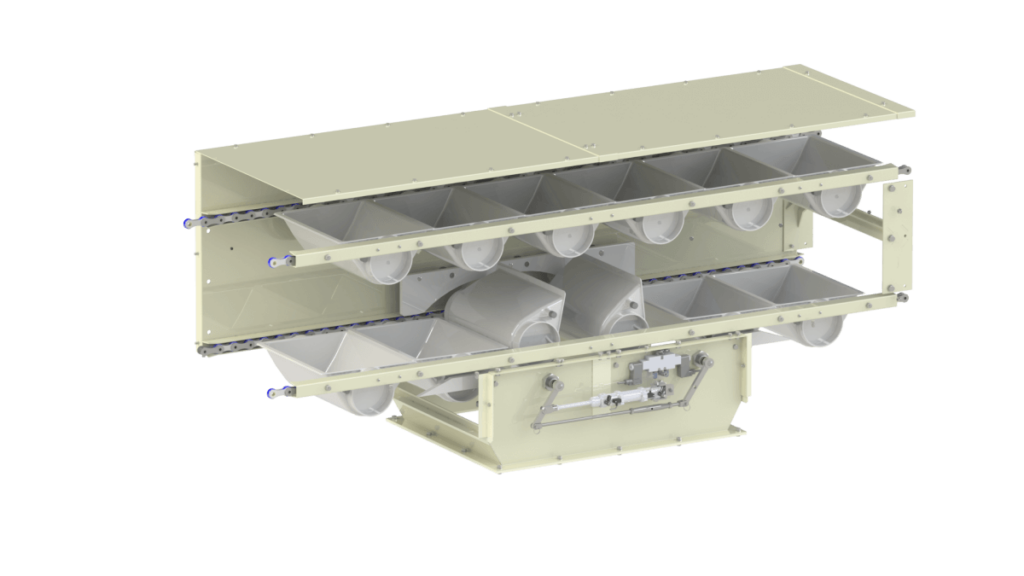

Installation on horizontal sections

The intermediate outlet may be installed according to requirements on the horizontal sections. CAD-designed curve guides ensure low friction and minimum wear. The intermediate outlet is activated by a compressed air cylinder that raises a curve guide to tilt and empty the buckets. The cylinders are equipped with position indicators with “reed switches”. The cylinder is controlled by a magnetic switch which enables activation from a central control panel.

Description

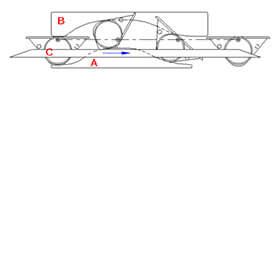

An emptying guide, which is lowered or raised by means of a compressed-air cylinder, controls the intermediate outlet. When the guide is in its lower position, the buckets will pass the guide without being affected. When the guide is raised, the buckets are tipped and thus emptied. The main movement is generated when the ring of the bucket slides along the raised guide (A). A static guide is installed above the bucket (B). This guide prevents the bucket from “tipping over” and leads the bucket back into horizontal position. The third guide makes the bucket enter correctly into the two other guides (C).

The actuator, fitted to the outlet´s exterior, is linked to the tipping mechanism (A) via two rocking levers. The actuator´s linear movement then forces the guide to lift up or go down when one of these levers is compressed. A screw spindle fitted under the actuator ensures that the motion of the other lever, and thereby the end of the guide, remain “parallel”. The screw spindle is also used to adjust the guide´s output curves to ensure steady movements when the buckets leave the guide.