Plate magnets including cleaning mechanism / extractor plate

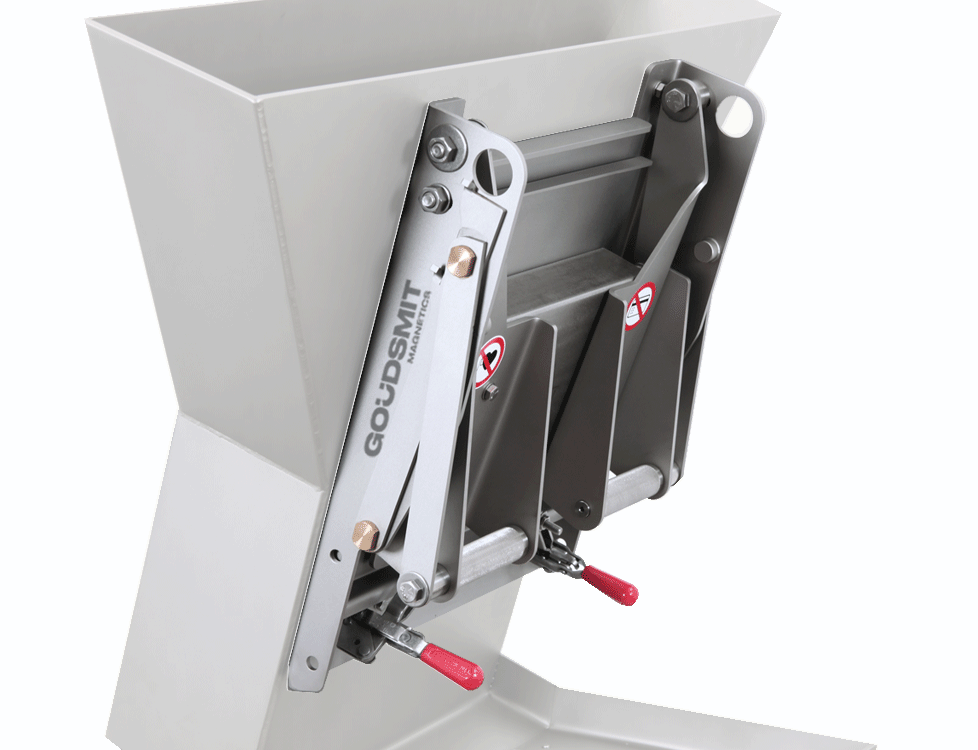

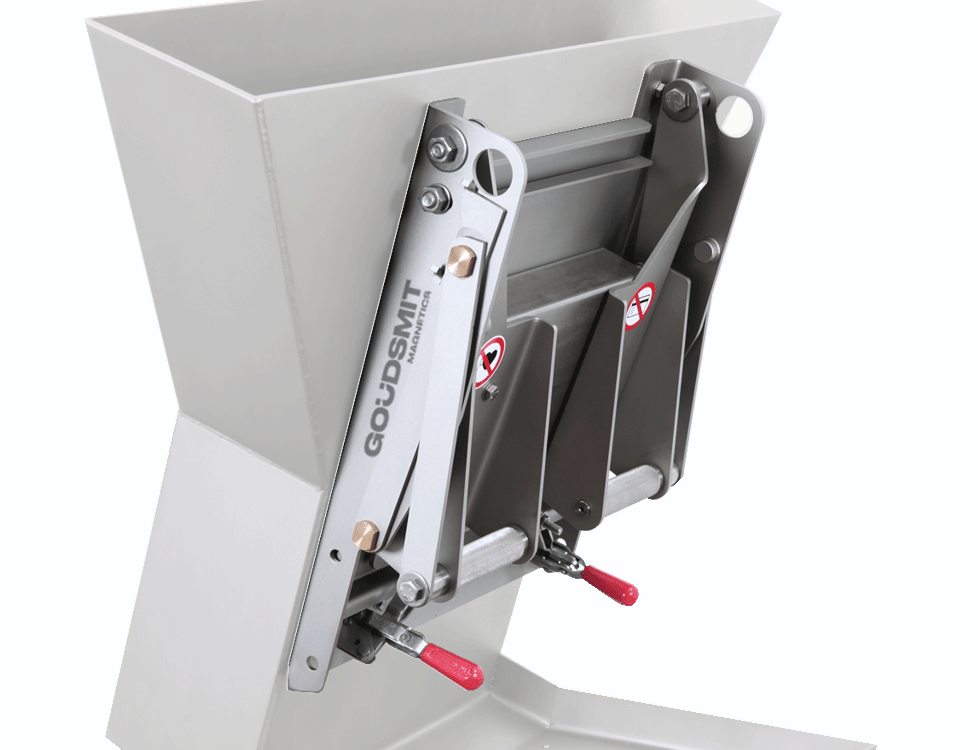

“Add-on chute” magnets – also known as chute magnets – are neodymium plate magnets with an attached extractor plate and a mounting structure that allows for self-installation on one of the sides of the product channel.

The magnetic system is used to remove ferrous impurities from powder, granules, or coarser raw materials in chutes or slides at an angle of up to 45°.

- Equipped with neodymium plate magnets

- Max. holding field 180 mm

- Captures Fe particles from 0.5 mm

- “Quick-cleaning” using extractor plates

- Max. installation angle of 45°

Construction & Function

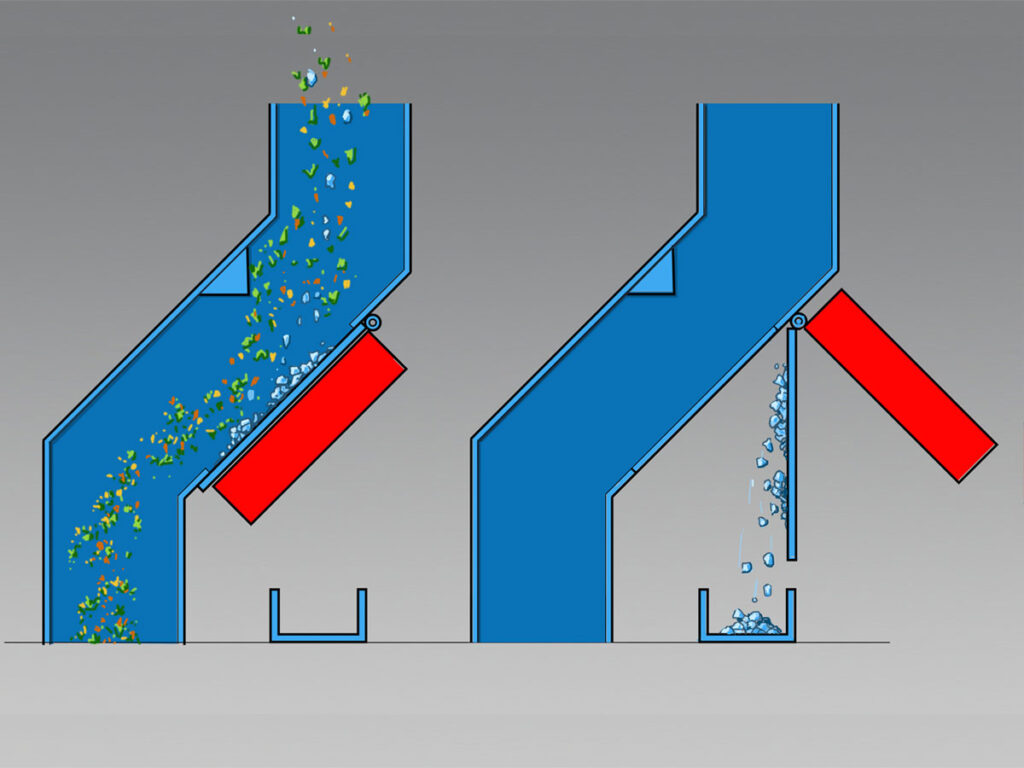

“Add-on chute” magnets are primarily used to remove ferrous impurities from powder, granules, and even coarser raw material flows in free-fall chutes or slides at an angle of up to 45°.

The magnets are equipped with neodymium plate magnets as a standard, which are extremely powerful, compact, and lightweight. The plate magnet is positioned behind a stainless steel extractor plate. They are held against the product channel by two clamps that are easy and quick to release.

“Add-on Chute” magnet is cleaned using the attached extractor plate for “quick cleaning”. When the attached extractor plate swings away from the magnet, the ferrous parts fall off the plate as soon as the plate is far enough away from the magnet.

It’s a simple solution for removing ferromagnetic impurities – you can easily install them yourself, and they ensure a high degree of separation.

Material system and magnet housing in stainless steel

Finish: sandblasted

Material seals: EPDM, FDA approved

For further information about our “Add-on Chute” magnets, please visit www.goudsmitmagnets.com“