Separation of ferromagnetic particles

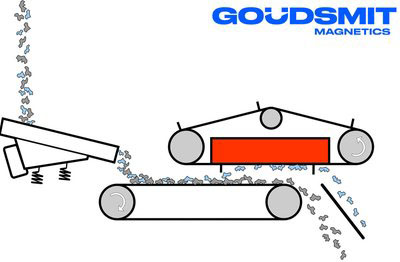

Head pulley magnets are suitable for placement in existing conveyor belt systems, for example, during bulk material handling or in the recycling industry. These magnets are effective for separating particles with challenging shapes for other magnet systems and for weakly magnetic particles. Cleaning is performed through continuous discharge of the iron particles. These magnets can be provided as an add-on solution to an existing setup or as a complete plug-and-play system.

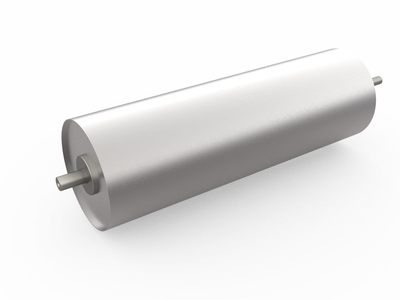

Head pulley magnets for installation: These magnets come in various magnetic field strengths, diameters, widths, or shaft types to suit different requirements.

Head pulley magnet systems: These systems are delivered fully equipped to customize everything for achieving the best degree of separation. There are many options available considering the product flow.

- Cost-effective and robust

- With neodymium or ferrite magnets

- Continuous automatic cleaning

- For belt widths 400-2000 mm

- Captures both Fe and weakly magnetic particles.

Add-on head pulley magnets

Head pulley magnets capture ferrous components as well as weakly magnetic particles and ensure their continuous disposal. They are suitable for installation, for example, on existing belt conveyors, during bulk material handling, or in the recycling industry.

- Cost-effective and robust

- With Neodymium or Ferrite magnets

- Permanent magnet

- Automatic cleaning (continuous)

- Customized solutions

For further information, visit www.goudsmitmagnets.com or download the “Recycling & sorting” brochure.

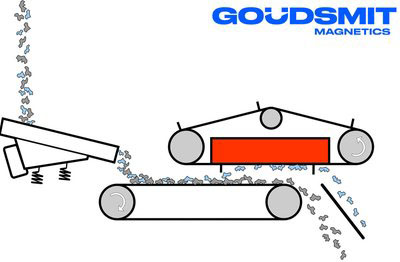

High gradient head pulley magnet systems

High gradient head pulley magnet systems are used to capture weakly magnetic particles and ensure their continuous disposal. Due to the limited magnetic field depth, this system is not suitable for use with high capacities.

- Very powerful

- Captures iron and weakly magnetic

- particles from 0.1 mm

- Continuous automatic cleaning

- For belt widths 600-800 mm

- Max layer thickness 30 mm

For further information, visit www.goudsmitmagnets.com or download the “Recycling & sorting” brochure.