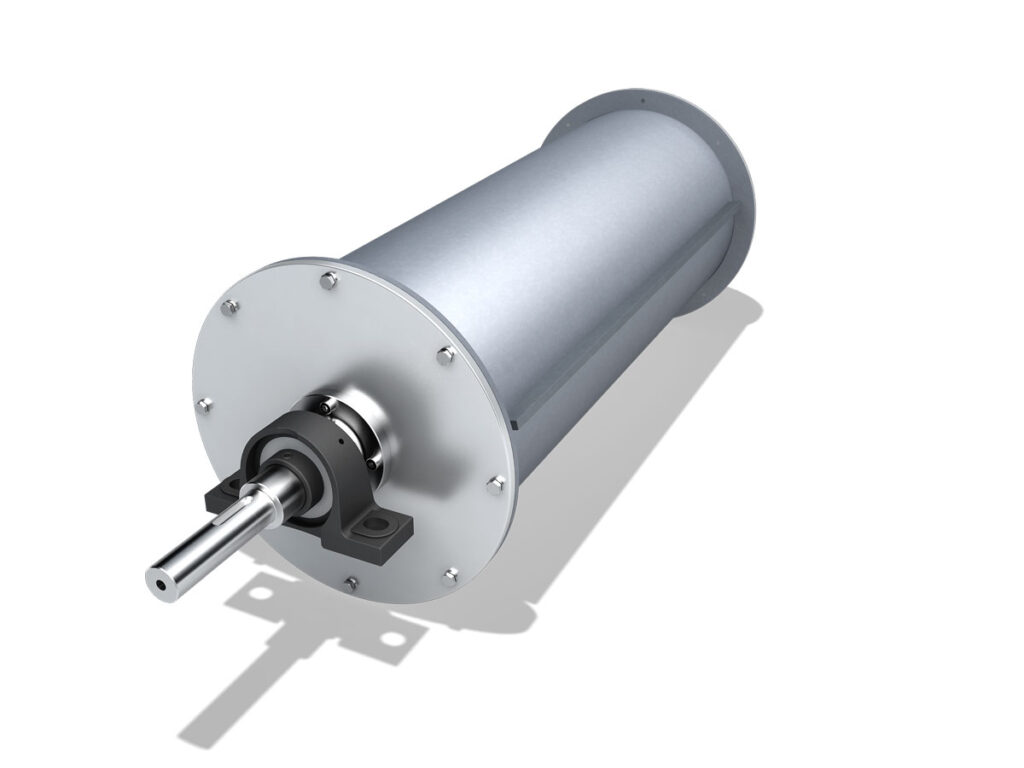

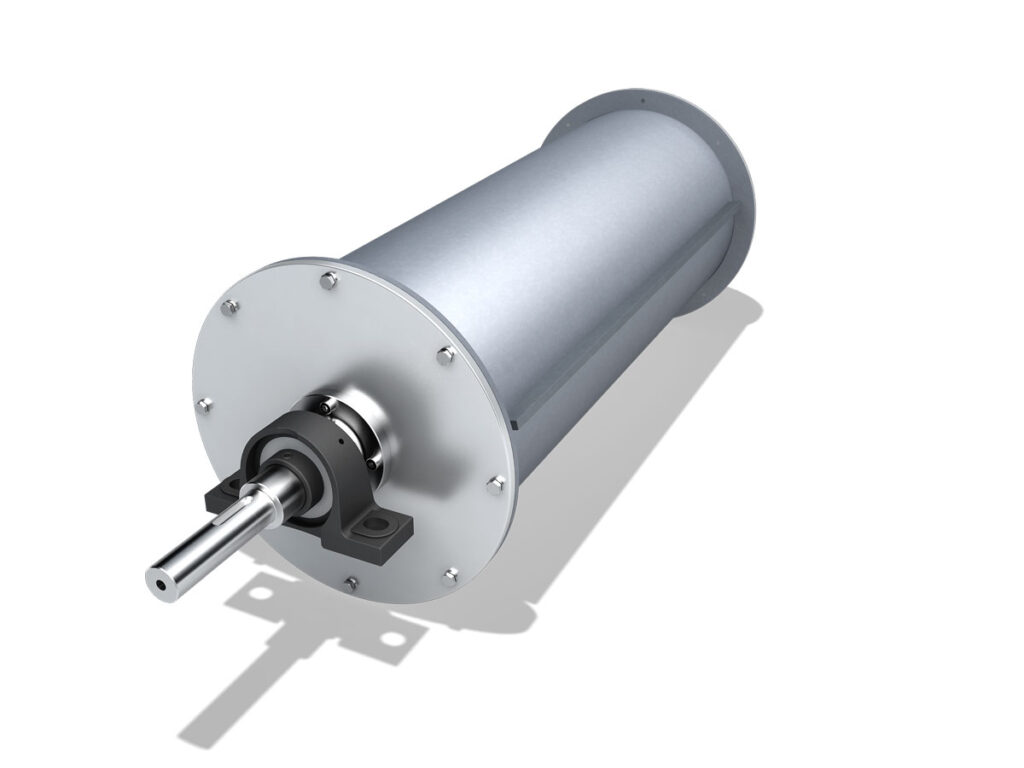

Stationary magnet in rotating stainless steel drum

Magnetic drum separators automatically or continuously separate large quantities of ferromagnetic (Fe) particles – such as iron and steel, or even weakly magnetic particles like processed stainless steel – from bulk product streams.

A drum magnet consists of a stationary magnetic segment around which a stainless steel sleeve rotates with cleats. The product stream falls over the sleeve, while the magnet attracts the ferromagnetic metal particles in the product. Cleats on the drum sleeve guide the attached particles to the bottom of the drum outside the magnetic field. Here, the particles will drop off and can be collected and/or removed. This is often achieved using a separation plate.

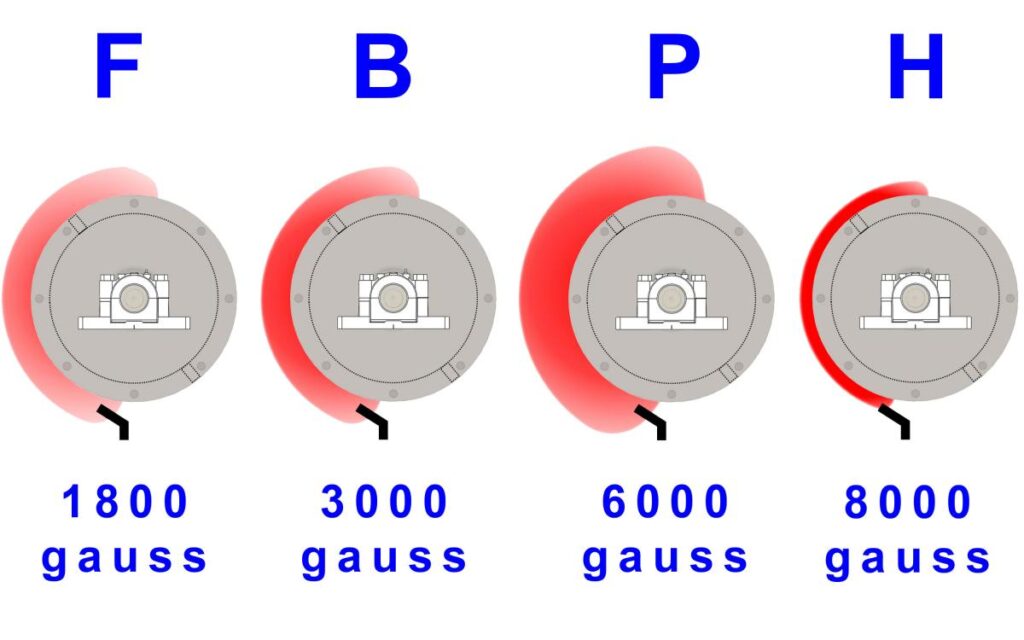

By utilizing different magnetic systems, it is possible to capture both ferromagnetic (strongly magnetic) and weakly magnetic particles.

- For coarser products and bulk streams

- High capacity (up to 550 m³/h)

- Suitable for sharp and abrasive particles

- Magnetic segment in a rotating drum

- Adjustable magnetic field.

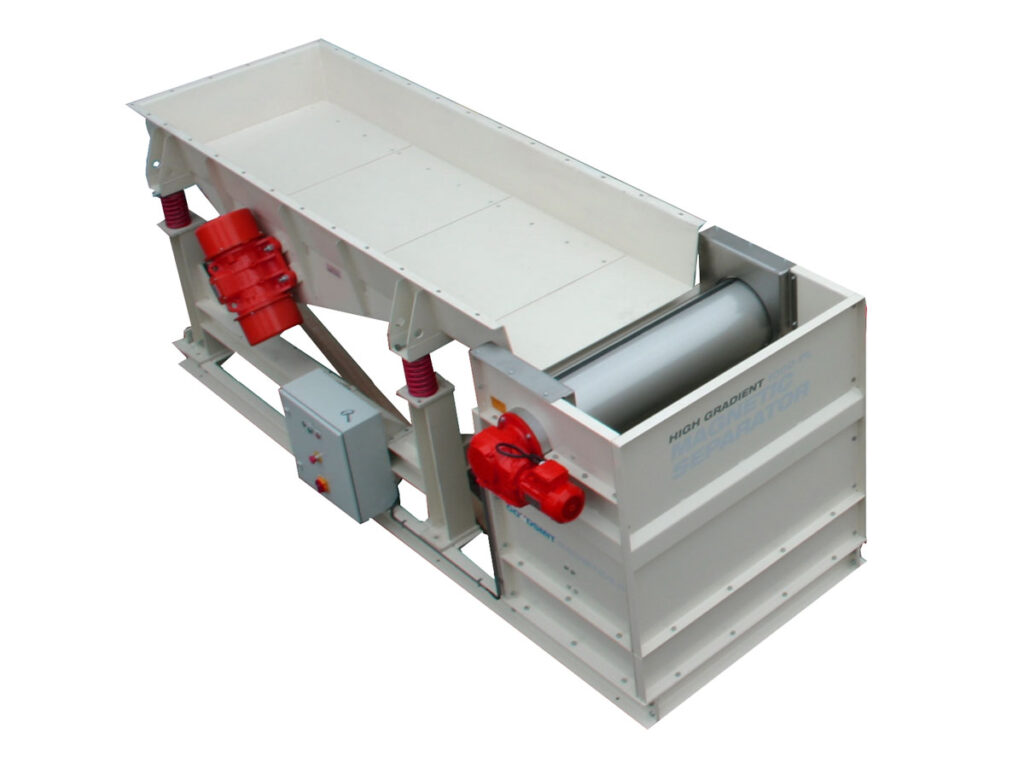

Magnetic drum separator in housing, standard type

This type of magnetic drum separator features an industrial finish. They remove 0.5-5 mm ferrous impurities from all types of non-food powders and granulates, fibers, or coarser raw materials in gravity-feed systems. They are equipped as standard with a 3000 gauss magnetic drum.

- Suitable for recycling or metal separation

- Capacity up to 300 m³/h

- Adjustable magnetic field

- Continuous automatic cleaning

- Ferrite / neodymium magnet (3000 gauss on the sleeve)

For further information, please visit www.goudsmitmagnets.com.

“Add-on” magnetic drum separator

This type of magnetic drum separator is suitable for placement after a vibrating feeder or for integration into a housing. It is easy to install and continuously removes coarse or sharp iron particles. It is available in different magnetic strengths and types for the separation of either strongly or weakly magnetic particles.

- High capacity (up to 550 m³/h)

- Various dimensions and flange types

- With Neodymium or Ferrite magnets

- For belt widths of 600-2000 mm

- Suitable for sharp or abrasive products

For further information, please visit www.goudsmitmagnets.com.

Permanent magnetic drum separator for waste

These robust, permanent drum magnets are used for processing larger quantities containing large or sharp components, such as: waste, metal mixtures, or steel slags.

If an overband magnet is not suitable due to heavy wear on the belt, this drum magnet is the solution. It functions as an overband magnet but has a wear-resistant shell.

The drum magnet can also be used in pre-separation processes for separating larger ferromagnetic metal parts >100mm. Due to the large drum diameter, the ferromagnetic parts will have an optimal contact surface with the magnet.

- Suitable for sharp and abrasive particles

- Non-switchable (permanent magnet)

- Automatic cleaning (continuous)

- Captures Fe particles from 50 – 250 mm

- For belt widths of 1000-2000 mm

For further information, please visit www.goudsmitmagnets.com

Electromagnetic drum separator for waste

These robust electromagnetic drum magnets are used for processing larger quantities containing large or sharp components, such as waste, metal mixtures, or steel slags.

If an overband magnet is not suitable due to extensive belt wear, this drum magnet is the solution. It functions like an overband magnet but features a durable shell.

The drum magnet can also be used in pre-separation processes for separating larger ferromagnetic metal parts >100mm. Due to the large drum diameter, the ferromagnetic parts will have an optimal contact surface with the magnet.

- “Switchable” (electromagnet)

- For belt widths of 1000-2000 mm

- Suitable for sharp or abrasive particles

- Captures Fe particles from 50 – 250 mm

- Automatic cleaning (continuous)

For more information, please visit www.goudsmitmagnets.com.