Removal or reduction of unwanted magnetism

Undesired magnetism costs both time and money. It attracts dirt, dust, or adhesive materials, reduces the quality of the end product, and leads to production downtime.

Demagnetization systems – also known as “degaussers” – remove residual magnetism (degauss) or reduce it to a negligible level. This decreases bearing wear, enables re-welding, and prevents measurement errors.

Goudsmit offers several demagnetization systems in their lineup and also provides on-site demagnetization services for your products.

- Technical expertise, production, and service

- Tailored to your requirements

- In-house testing center in the Netherlands

- 60 years of experience

- Quality and reliability

Demagnetization Tunnels

Demagnetization tunnels (or coils) demagnetize long or packaged products. They are also suitable for demagnetizing steel objects with irregular surfaces, as well as for both thin-walled and more compact products. This includes items like pipes, shafts, drills, gears, and pistons.

They are also available with conveyors or roller conveyors for automated demagnetization processes.

High-frequency Demagnetization Tunnels

High-frequency tunnels demagnetize thin-walled objects at a frequency of 50/60 Hz. This applies to items such as pipes, gears, nuts and bolts, steel grit from shot blasting, drills, etc. The system can be directly connected to the power grid.

Demagnetization Tunnel with Rectangular Passage

Tunnels with rectangular passage demagnetize long objects and materials with an uneven surface. They are suitable for thin objects with a wall thickness of up to 10 mm or for solid objects with a thickness of up to 20 mm, such as drills and other tools, pipes, gears, bolts, nuts, and other fastening elements, steel components in the automotive industry, etc. They are also available with conveyor systems or roller conveyors for automated processes.

- Max. penetration depth 10-20 mm

- Frequency 50 Hz

- Available with conveyor system

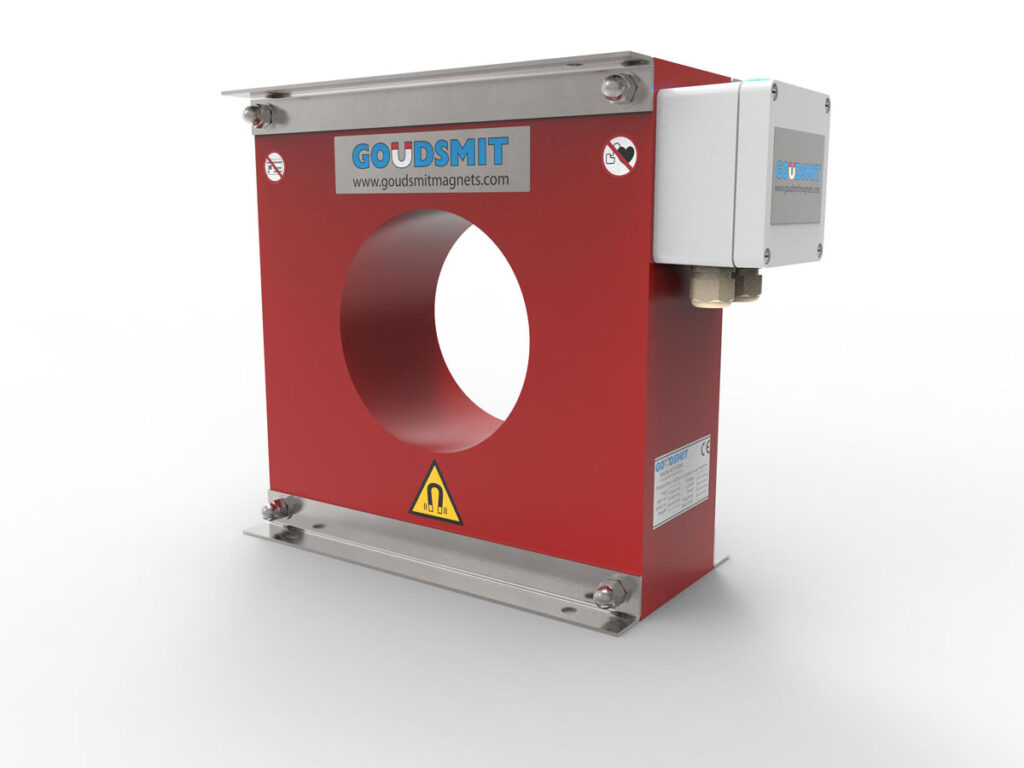

Demagnetization Tunnel with Circular Passage

Demagnetization tunnels with circular passage are suitable for installation in piping systems and for demagnetizing round, thin-walled objects (with a wall thickness of up to 10 mm). The system is suitable for demagnetizing items such as pipes, ball bearings, steel dust in air filter systems, steel grit from shot blasting, etc. The demagnetization tunnel is available in combination with a conveyor system or roller conveyor for automated processes.

- Max. penetration depth 10-20 mm

- Frequency 50 Hz

- Available with transport system

For further information, please visit www.goudsmitmagnets.com

For more information, visit www.goudsmitmagnets.com

Low-Frequency Demagnetization Tunnels

Low-frequency tunnels are suitable for thick-walled objects, objects made of hardened steel, or solid objects such as rails, shafts, pistons, or cases where multiple objects are packed together and require special control.

Demagnetization Tunnel – Low-Frequency

These tunnels demagnetize thick-walled or solid objects. This also applies to hardened steel or densely packed objects. Low-frequency demagnetization tunnels operate at a frequency between 0.1 and 3 Hz. This provides the maximum penetration depth. It is suitable for objects with a thickness of up to 500 mm, including untreated steel. Available in combination with a conveyor system or roller conveyor for automated processes.

- Max. penetration depth 500 mm

- Frequency 0.1 – 3 Hz

- For thick-walled or densely packed objects

- Available with transport system

For more information, visit www.goudsmitmagnets.com

Demagnetization Plates

Demagnetization plates are suitable for demagnetizing flat or single-sided products with a thickness of up to 10 mm. A demagnetization plate is intended for placement where there is limited space for the installation of a demagnetization tunnel or for installation under an existing conveyor belt.

Also available in combination with a conveyor system or belt conveyor for automated processes.

Demagnetization Plates

Demagnetization plates are suitable for demagnetizing flat or single-sided products with a thickness of up to 10 mm. A demagnetization plate is intended for placement where there is limited space for the installation of a demagnetization tunnel or for installation under an existing conveyor belt. Available in combination with a conveyor system or belt conveyor for automated processes.

- Compact design

- Max. demagnetization surface area 420×300 mm

- Max. penetration depth 10-20 mm

- Available with transport system

For more information, visit www.goudsmitmagnets.com

Handheld Demagnetization Equipment

Handheld demagnetization equipment, also known as demagnetization tools, is compact and lightweight. The equipment is particularly suitable for demagnetizing tools or machine parts that are difficult to access with other equipment.

Demagnetization Rod

Demagnetization rods, also known as demagnetization bars, are suitable for demagnetizing tools and machine parts in hard-to-reach places. They are used in workshops, by tool manufacturers, machine manufacturers, and more.

- Precise Max. penetration depth 10 mm (single-sided)

- Stainless steel casing

- Includes cable

Handheld Demagnetization Equipment with Round Passage

This handheld demagnetization tool, also known as a demagnetization coil, is ideal for demagnetizing tools or small objects. It is also used for items like drills and chisels.

Max. penetration depth 10 mm (on all sides)

Plastic casing

Includes cable.

Suitable for demagnetizing smaller objects

See further information at www.goudsmitmagnets.com

See additional information at www.goudsmitmagnets.com