Recovery of metals from waste materials

Goudsmit has developed a range of separators capable of extracting metal particles from waste materials for recycling. The systems can sort product streams, separate metals from each other or from other materials. They can eliminate the presence of metallic impurities from raw materials or capture valuable metals from product streams.

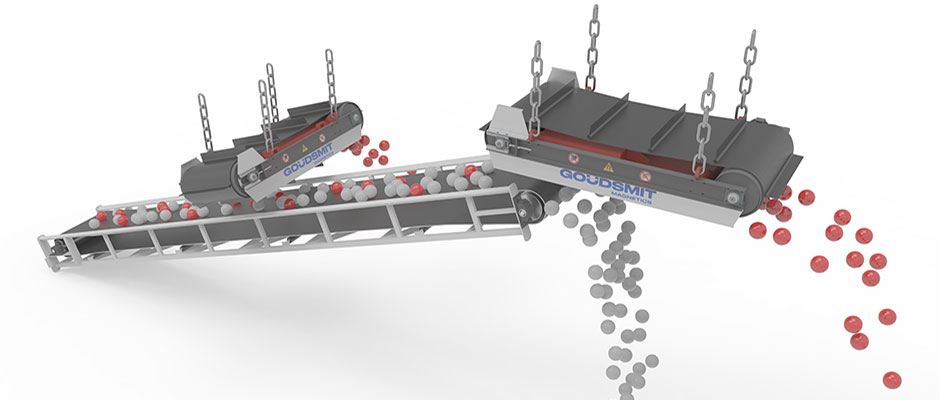

Goudsmit’s magnetic separators for the recycling industry feature an extremely robust construction, ensuring optimal performance even under the most demanding conditions. In several cases, a number of separators are combined by placing them in series.

- In-house test center at Goudsmit in the Netherlands

- Delivered according to customer needs and requirements

- Combined Fe and Non-Fe separation possible

- Quality and reliability

Eddy current separators

Combined separation of ferrous and non-ferrous metals A Goudsmit Eddy current separator or NF separator (eddy current separator) is a metal sorting unit that allows

Magnetic head pulleys

Separation of ferromagnetic particles Head pulley magnets are suitable for placement in existing conveyor belt systems, for example, during bulk material handling or in the

Overband magnets

Continuous removal of ferromagnetic particles Overband magnets – also known as conveyor belt magnets – remove iron particles from raw materials and automatically and continuously

Suspension magnets

For installation over conveyor belts Block and Plate Magnets remove ferromagnetic (Fe) particles such as iron and steel, or even weakly magnetic particles like processed

Magnetic drum separators

Removes unwanted ferromagnetic particles Goudsmit drum magnets are used for the automatic, continuous removal of iron-containing and even weakly magnetic impurities. Drum magnets – also