Filtering of unwanted metal particles

Magnetic separators filter and remove metal impurities from product streams. They enhance product quality and prevent damage to production equipment. Magnets operate consistently, ensuring high reliability.

Metal impurities, also known as foreign objects, include items such as staples, nails, screws from packaging, bolts and nuts that have come loose due to vibration, worn steel components, particles of stainless steel from machinery, or rust particles resulting from corrosion.

Detecting and removing these contaminants prevents rejected batches, product recalls, unplanned production stops, high costs, reputation damage, and liability claims.

Magnetic separators can be used, among other things:

- To ensure the final quality of a product or product flow.

- For inspection during the addition of various powdered or liquid substances.

- To prevent damage to injection molding machines, extruders, mixers, mills, and other process equipment.

- To reduce the risk of dust explosions (ATEX).

Magnetic field meters

Measurement of magnetic fields When it comes to measuring magnetic fields, we offer a range of options for various applications with different characteristics. With magnetic

Magnetic inspection rods

Neodymium magnet rod integrated into the pipe A magnetic inspection rod allows you to investigate whether the product is contaminated with ferromagnetic (Fe) particles. The

Magnetic bars

Filtering out magnetic impurities from product streams These highly powerful Neoflux® (neodymium) magnet rods / magnetic bars are designed to remove small ferromagnetic impurities (such

Plate & block magnetic

Filtering out unwanted ferromagnetic particles Plate magnets are cost-effective, robust magnets with a deep, powerful magnetic field. They are therefore suitable for removing medium to

“Add-on Chute” magnets

Plate magnets including cleaning mechanism / extractor plate “Add-on chute” magnets – also known as chute magnets – are neodymium plate magnets with an attached

Magnetic grids

Detects even the smallest iron particles Goudsmit magnetic grids – or grate magnets – are often placed at a filling point or a receiving funnel.

Magnetic drum separators

Removes unwanted ferromagnetic particles Goudsmit drum magnets are used for the automatic, continuous removal of iron-containing and even weakly magnetic impurities. Drum magnets – also

Bullet magnets

For high-capacity chute systems Goudsmit bullet magnets are equipped with a large cylindrical magnet core, positioned at the center of the product flow. They filter

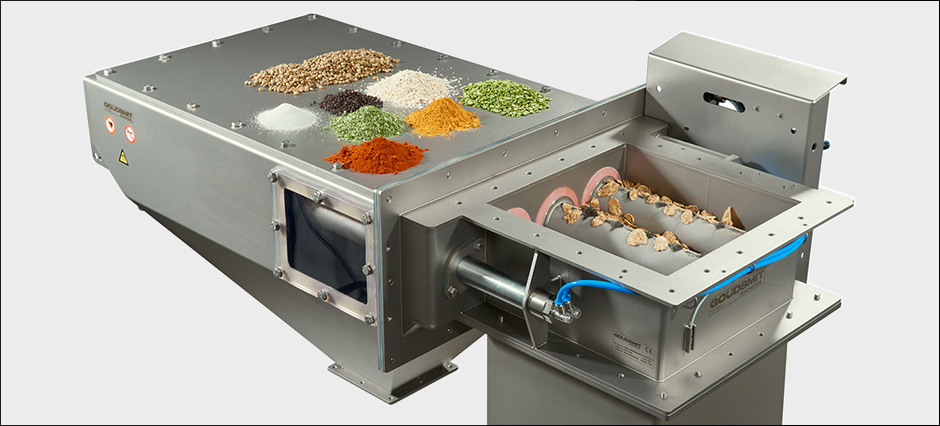

Cleanflow magnets

To remove iron-containing impurities from granules or powder Goudsmit Cleanflow magnets (magnetic separators with drawer/extraction) are magnetic separators built into a housing, equipped with powerful